A Beginner’s Guide to Understanding the Functionality of Industrial Scales

A Beginner’s Guide to Understanding the Functionality of Industrial Scales

Blog Article

Why to Pick Industrial Scales for Accurate Weight Dimension in Different Industries

In an age where precision is paramount, the option of commercial ranges for precise weight dimension plays an essential duty throughout varied fields. These scales not only boost operational effectiveness yet additionally make certain conformity with governing criteria, impacting everything from production to delivery. Their durable layout and progressed innovation satisfy various applications, reinforcing the demand for careful weight monitoring. Recognizing the subtleties of these scales is vital for any company intending to optimize processes and alleviate pricey errors. The inquiry stays: what certain elements should one take into consideration when choosing the right scale for their special functional needs?

Significance of Accurate Weight Measurement

In the realm of industrial operations, the relevance of exact weight dimension can not be overemphasized. Precise weight measurement is foundational across numerous fields, affecting both functional efficiency and product top quality - Industrial Scales. It acts as a vital aspect in supply management, making certain that materials are properly made up, therefore reducing waste and lowering expenses

In manufacturing, accurate weight measurement straight affects production processes. Anomalies in weight can cause ineffective products or excessive resource allotment, impacting total success. Furthermore, in sectors such as drugs and food manufacturing, adherence to rigorous weight requirements is essential for regulatory compliance and consumer safety and security.

Moreover, precise weight measurements assist in reliable logistics and supply chain monitoring. Properly weighed shipments guarantee that transport costs are optimized and that inventory levels are maintained precisely, thereby protecting against stock shortages or overstock scenarios.

Kinds Of Industrial Scales

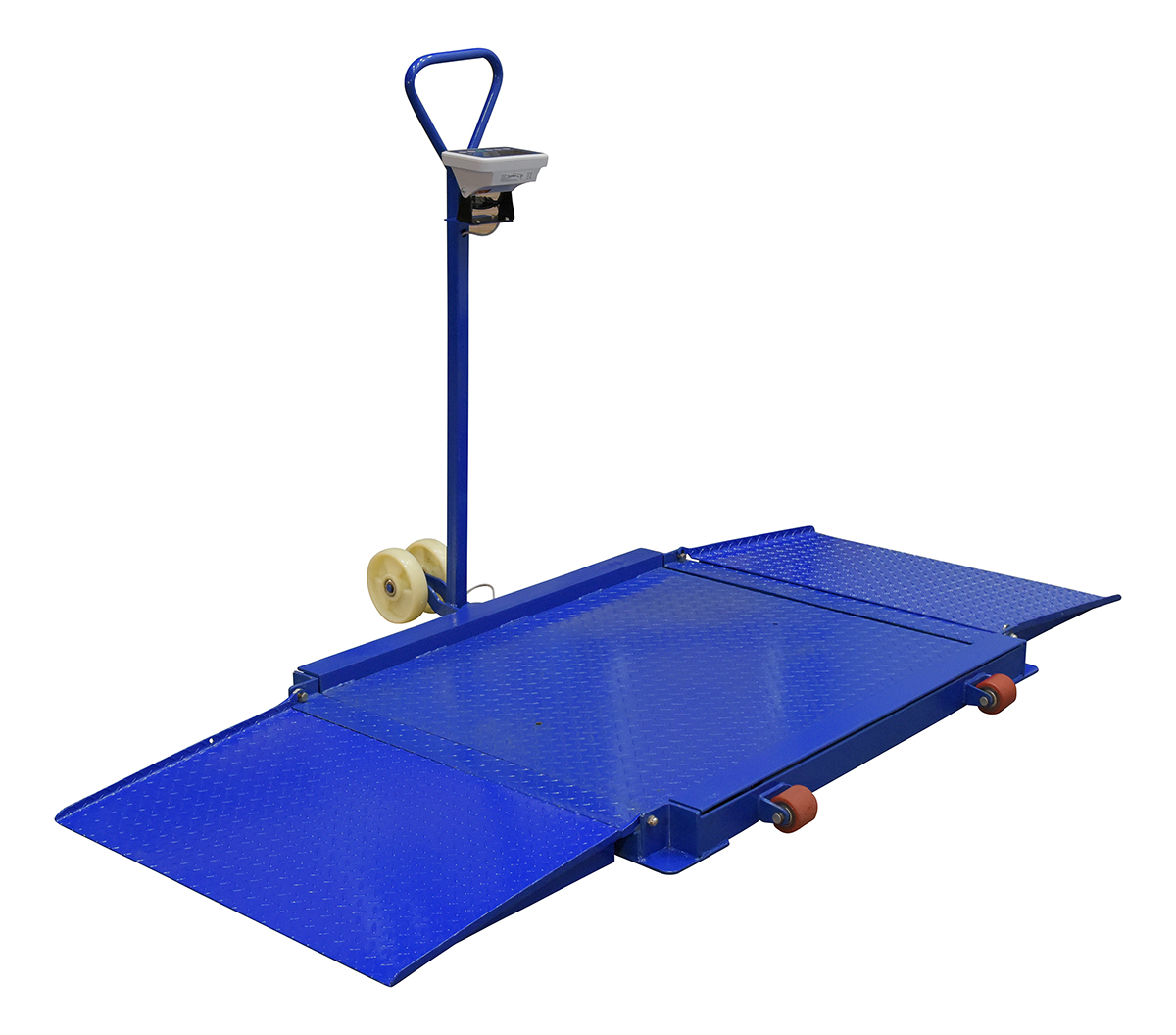

A broad selection of industrial scales are offered, each developed to fulfill certain measurement requires across varied sectors. Common kinds consist of flooring ranges, which are durable and suitable for considering big items or pallets in stockrooms and distribution. Bench scales are smaller sized and optimal for lighter products, typically made use of in retail settings or producing for specific portion control.

One more group is portable ranges, which offer the versatility to be relocated quickly around work websites, making them optimal for area operations or short-term setups. Precision scales, on the other hand, are developed for high precision and are often made use of in labs and quality assurance settings.

Load cells are vital elements in numerous industrial ranges, converting push into an electrical signal for exact analyses. In addition, truck scales give the means to consider heavy automobiles and their lots, making sure conformity with policies and enhancing logistics.

Lastly, checkweighers automatically compare the weight of products against pre-programmed limits, improving quality assurance in manufacturing lines (Industrial Scales). Each kind of commercial range offers a special function, satisfying the specific needs of markets such as manufacturing, logistics, food processing, and pharmaceuticals

Benefits of Using Industrial Scales

Constantly using industrial scales supplies substantial benefits across various sectors. Among the key benefits is improved accuracy in weight measurement, which is essential for maintaining quality standards and regulative compliance. Precise dimensions prevent expensive errors in production, delivery, and supply administration, eventually resulting in raised functional efficiency.

In addition, industrial ranges are created for longevity and toughness, allowing them to withstand harsh settings commonly located in production and warehousing. This durability makes certain a lengthy life-span, lowering the demand for frequent replacements and upkeep costs.

Moreover, using commercial ranges improves safety and security and his response decreases waste. By ensuring that products are weighed accurately, firms can avoid overwhelming cars, which can lead to mishaps and fines.

Applications Across Different Industries

Industrial ranges play a pivotal role in numerous sectors, including production, logistics, food handling, and pharmaceuticals. In manufacturing, these scales are important for guaranteeing that basic materials are measured properly, consequently preserving product quality and uniformity (Industrial Scales). Precision in weight measurement straight influences production efficiency and price monitoring

In logistics, commercial scales assist in the exact considering of deliveries, which is critical for sticking to maximizing and delivering policies freight prices. Precise weight information assists improve procedures and improves supply chain management.

The food handling industry counts heavily on commercial scales for conformity with health and wellness laws. They are utilized to consider components precisely, making certain that formulations fulfill both high quality criteria and legal needs. This is crucial not only for consumer safety and security yet also for keeping brand integrity.

Drug companies use industrial ranges to make sure accurate does in medication production, where also the tiniest discrepancy can have considerable effects. Compliance with stringent governing criteria makes exact weight measurement vital in this sector.

When Picking Scales,## Aspects to Think About.

Picking the right scale for details applications needs navigate to this site careful factor to consider of a number of variables. Most importantly, the ability of the scale is essential; it must fit the maximum weight of the things being measured without exceeding its limitations. In addition, the readability, or tiniest increment the scale can precisely display, is essential for precision, specifically in markets where weight discrepancies can result in considerable monetary losses or safety and security worries.

Ecological problems likewise play a substantial duty in range option. Ranges made use of in corrosive or damp settings might call for specific materials to make sure toughness. Similarly, portability might be vital in specific applications, demanding battery-operated and lightweight designs.

Verdict

In conclusion, the selection of commercial scales is pivotal for making sure exact weight measurement throughout diverse markets. Their ability to provide exact readings not just improves operational efficiency however additionally sustains regulative compliance and supply administration. The adaptability and resilience of these ranges promote their application in various markets, eventually adding to set you back decrease and enhanced item quality. Thus, purchasing high-quality commercial ranges is necessary for companies try these out aiming to maintain high criteria and optimize productivity.

Report this page